Follow us on social media:

Runtime: 8:39

0:07 Tesla on Track to Top 100,000 Sales This Quarter

0:46 Problems with Tesla’s Autopilot Name?

1:08 EVs Could Cost People Their Jobs

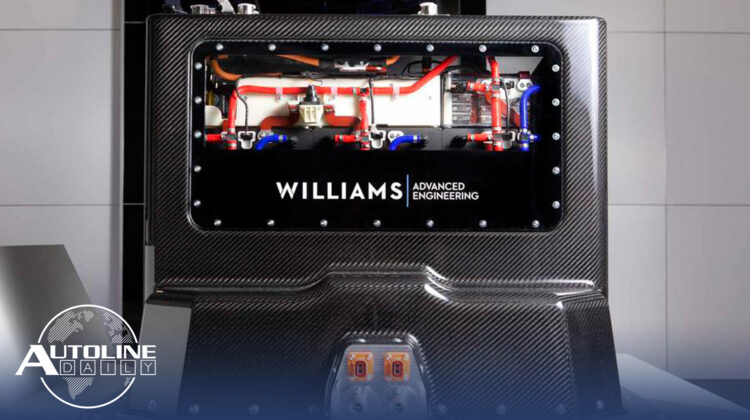

2:48 Williams Develops Innovative EV Battery

4:18 Traditional OEMs Focus on EV Reliability, Not Range

5:29 2020 Charger Lineup Pricing Release

6:33 UAW Strike Hitting Suppliers Hard

Visit our sponsors to thank them for their support of Autoline Daily: Bridgestone and Kiekert.

This is Autoline Daily reporting on all aspects of the global automotive industry.

TESLA ON TRACK TO TOP 100,000 SALES

Could Tesla have a blow out sales quarter? Sure looks that way. Yesterday Elon Musk sent an email to employees saying the company is on track to sell 110,000 cars this quarter, the first time its sales ever cracked the 100,000 mark. And the stock jumped twenty bucks a share on the news. This could be an impressive milestone for Tesla. It still only has one assembly plant and it’s lost most of its sales subsidies in the U.S. If the company does sell over 100,000 cars it shows that demand is strong and that there’s a lot more upside potential once it gets its plant in China up to speed.

PROBLEM WITH TESLA’S AUTOPILOT NAME

Speaking of Tesla, I had an interesting phone interview with Jason Torchinsky, a Senior Editor at Jalopnik.com who just wrote a book about Autonomous cars called Robot Take the Wheel, and he’s quite critical of Tesla’s Autopilot system, starting with the name, Autopilot. You can find that interview right now on our YouTube channel.

EVs COULD COST PEOPLE THEIR JOBS

At some point in the future electric cars are going to catch on and that poses a risk for the tens of thousands of workers who manufacture traditional piston powertrains. A piston engine car uses over 100 forgings. An EV uses less than 10. A traditional car uses 150 pounds of aluminum castings. An EV uses 80. And of course EVs don’t need radiators, exhaust systems, mufflers and a host of other components. Even if electric cars only reach 25% of all sales, that could eliminate 30,000 jobs just in the U.S. alone. And it’s not as if those jobs can transition to making EV batteries, because battery assembly is already 99% automated. We probably have about a decade before this really hits home and every country that makes cars better start making plans right now to figure out how they’re going to deal with this job displacement.

WILLIAMS DEVELOPS INNOVATIVE BATTERY

Williams Advanced Engineering is the battery supplier for the all-electric racing series Formula E and it’s pumping some of the knowledge it learned into a very innovative battery pack. It uses what they call Adaptive Multi-Chem technology that combines Samsung cylindrical cells with pouch cells from A123 systems. The cells are separated from each other in each module, with the cylindrical cells providing energy density and the pouches giving high power. Each module uses a bi-directional DC/DC converter to deliver the energy, even allowing energy from one cell to power up the other. This setup results in a 37% increase in energy density. The 60 kWh battery has a peak power output of 550 kW, which it can deploy in a 20-second pulse and it can absorb that same amount of energy in regeneration for 10 seconds. The pack is also lighter. Including the outer case it weighs 385 kilograms or roughly 850 pounds. For comparison, the 60 kWh battery in the Chevy Bolt weighs 960 pounds. Williams says the new battery would be a good application in motorsports, hypercars or even airplanes.

TRADITIONAL OEMs FOCUS ON EV RELIABILITY, NOT RANGE

Why is it that electric vehicles from traditional automakers can’t match the range of Tesla’s? Could it be that they’re scared? Scared of disappointing and losing their customers? Jalopnik recently did an interesting comparison with the Audi e-tron. It has a 95 kWh battery that provides 204 miles of range, which is way less than the Model S’s 370 miles from a 100 kWh battery. But because charging a battery to full capacity is not good for it, Audi only allows 83.6 kWh of the battery to be used. The e-tron also has a pretty intense cooling system for both the battery and motors, which saps more power. Audi even says it could have provided more range but its research suggests that the majority of its customers would charge overnight at home, so more range is less of a concern. This kind of surprises us. All the consumer surveys show that driving range is a major concern for people considering EVs. Besides, Tesla’s batteries have proven to be quite reliable..

CHARGER/HELLCAT WIDEBODY PRICES RELEASED

OK, enough of all that EV stuff. Let’s talk muscle cars for the moment. Dodge just announced prices for the 2020 Charger lineup which now includes the Charger Scat Pack Widebody and Hellcat Widebody, and the limited production 50th Anniversary Daytona Charger, which adds an extra 10 horsepower and is priced at just over $74,000. The Charger Hellcat Widebody gets a minor grille facelift and extra interior options and costs just under $70,000. The Scat Pack Widebody has less horsepower than the Hellcat Widebody but offers suspension perks and costs just under fifty grand. And if you have that kind of money burning a hole in your pocket, they all go on sale early next year. (Prices do not include $1,495 destination charge.)

UAW STRIKE HITTING SUPPLIERS HARD

The UAW strike is closing in on two weeks long, and it’s really starting to hurt a lot of innocent bystanders. Obviously it’s impacting the hourly workers at General Motors and is costing the company a lot of money. But it’s also starting to hurt a lot of other people.

Suppliers to GM are laying off thousands of hourly workers. While some of the large multi-national suppliers have been able to temporarily assign their workers to doing maintenance or taking training, smaller suppliers don’t have that luxury. They just lay their people off. And these are people who make less money than UAW workers, don’t have the kind of benefits they do, and who don’t get any strike pay.

This is one of the issues I have with the union and its strike strategy. It talks about how insensitive General Motors is, but the union is equally insensitive to working men and women who don’t belong to the union. And while GM will pay its hourly workers an $8,000 signing bonus for settling the strike, those supplier workers will get nothing. In many cases that strike is going to cost them at least two weeks pay, or more if the strike goes on longer.

So for me, the cry of Solidarity Forever rings a bit hollow, when I see the hardships it’s causing for so many others. Let’s hope that strike gets settled this weekend.

And with that we wrap up today’s report. Thanks for watching and we’ll see you back here on Monday.

Thanks to our partner for embedding Autoline Daily on its website: WardsAuto.com

John McElroy is an influential thought leader in the automotive industry. He is a journalist, lecturer, commentator and entrepreneur. He created “Autoline Daily,” the first industry webcast of industry news and analysis.