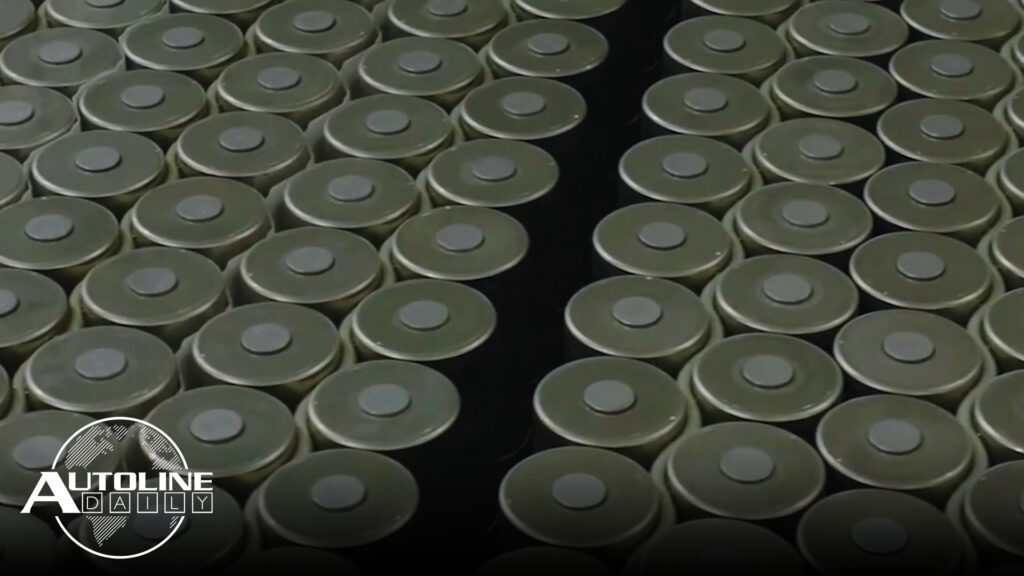

AD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts Chinese OEMs Will Launch U.S. Joint Ventures In 2026; Ford Talks with Geely To Fill Excess Factory Capacity in Spain

Listen to “AD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts…

Latest Posts

The Secret to Seamless Manufacturing: Fives DyAG on the Future of Systems Integration – Autoline Exclusives

In this exclusive Autoline interview, we sit down with the experts at Fives DyAG, a powerhouse in industrial…

AD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts Chinese OEMs Will Launch U.S. Joint Ventures In 2026; Ford Talks with Geely To Fill Excess Factory Capacity in Spain

Listen to “AD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts…

AD #4225 – Most Dealers Not Recouping EV Investments; Waymo More Valuable Than Most Automakers; Toyota & Honda Overtake the Detroit 3 in Canada

Listen to “AD #4225 – Most Dealers Not Recouping EV Investments; Waymo More Valuable Than Most Automakers; Toyota…

AD #4224 – Is Ford Eyeing Chinese Partners to Save Blue Oval City?; Scout Pivots to EREVs as 85% Of Customers Reject BEV; Canada Demands GM Pay Back Millions in Subsidies

Listen to “AD #4224 – Is Ford Eyeing Chinese Partners to Save Blue Oval City?; Scout Pivots to…

Autoline on the Road

See All PostsGM & Intrepid Control Systems Slash Vehicle Data Logging Time from Hours to Minutes – CES 2026

Collecting data during vehicle testing can be a burden. That’s why GM and Intrepid Control Systems teamed up…

Measuring Your Brainwaves With A Headrest Sensor – CES 2026

Did you know that your brain emits brainwaves that transmit outside of your skull? Neumo developed a sensor…

CONTINUE READING Measuring Your Brainwaves With A Headrest Sensor – CES 2026

Autoline Daily

See All PostsAD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts Chinese OEMs Will Launch U.S. Joint Ventures In 2026; Ford Talks with Geely To Fill Excess Factory Capacity in Spain

Listen to “AD #4226 – Tesla Mass Produces Dry Electrodes to Slash Costs By $1 Billion; Analyst Predicts…

AD #4225 – Most Dealers Not Recouping EV Investments; Waymo More Valuable Than Most Automakers; Toyota & Honda Overtake the Detroit 3 in Canada

Listen to “AD #4225 – Most Dealers Not Recouping EV Investments; Waymo More Valuable Than Most Automakers; Toyota…

Autoline After Hours

See All PostsAAH #776 – The Death of the Dashboard? The Radical Future of Car Interiors

CONTINUE READING AAH #776 – The Death of the Dashboard? The Radical Future of Car Interiors

AAH #775 – Scout Motors REVIVAL: Beating Tesla & Rivian with Buttons and Range!

CONTINUE READING AAH #775 – Scout Motors REVIVAL: Beating Tesla & Rivian with Buttons and Range!

Car Reviews

See All PostsThis New K4 Hatchback Provides a Golden Opportunity for Kia – Autoline Exclusives

The new K4 is already doing better than the Forte, which it replaces, selling about 10,000 units a…

CONTINUE READING This New K4 Hatchback Provides a Golden Opportunity for Kia – Autoline Exclusives

The EV4 is Kia’s 1st All-Electric Sedan – Autoline Exclusives

In this video we go over some of the details of Kia’s first all-electric sedan, the EV4, with…

CONTINUE READING The EV4 is Kia’s 1st All-Electric Sedan – Autoline Exclusives

Industry Interviews

See All PostsThe Secret to Seamless Manufacturing: Fives DyAG on the Future of Systems Integration – Autoline Exclusives

In this exclusive Autoline interview, we sit down with the experts at Fives DyAG, a powerhouse in industrial…

Is This the End of Gas Stations? Aptera Co-CEO Steve Fambro on the Solar EV Revolution – Autoline Exclusives

A lot has been written about Aptera, the car. But not so much about the business of the…